Inspection System

Consistently delivering safe, reliable products requires a specialized check system to support sites of production. Shinobu Foods has established microbiology laboratories at our head office and within production plants to inspect product condition and sanitation control at sites of production to check whether the system is capable of producing safe, reliable products.

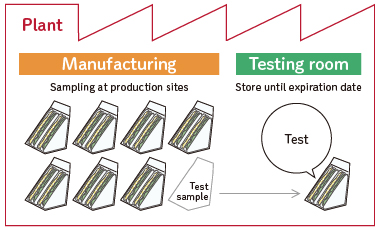

Product Testing

We take daily samples from production lines for testing, store these until their expiration date, and perform microbiological testing to verify whether they meet standards.

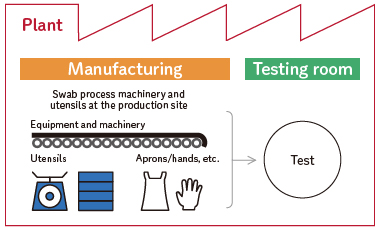

Swab Testing

We also check the sanitation status of production equipment and tools. After cleaning or during use, we perform swab tests on machinery and utensils used in processes to verify whether they have been cleaned and disinfected properly according to procedures.

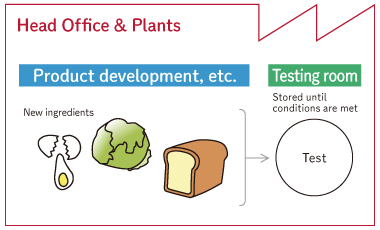

New Ingredient Testing

New ingredients are assessed for suitability in products based on the results of microbiological testing. Items that do not meet our internal standards are not used in our products.

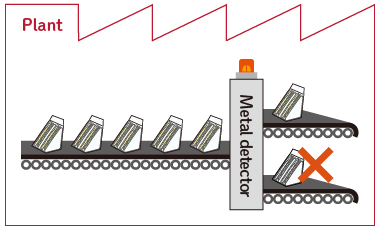

Metal Detection

All products are checked for contamination with metal objects using metal detectors after packaging.

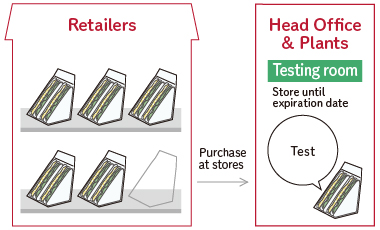

Testing of Products From Stores

We buy back products of ours sold in stores, store them at specified temperatures until the expiration date, and then perform microbiological testing. This is to check for any issues with the products at the point of consumption.